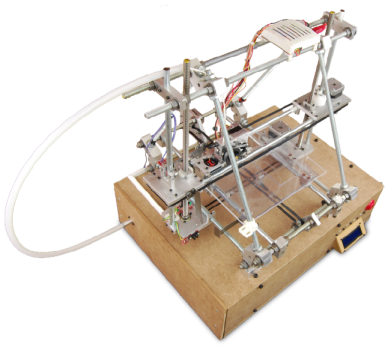

A great way to speed up the design process is to have a way to quickly make prototypes of objects to see how they look/feel/behave physically. This is especially true when designing something to be ergonomic. Always wanting to take my design skills and resources to the next level I decided that I needed a rapid prototype machine to "print" objects from 3D models. Unfortunately rapid prototype machines are quite expensive, but it turns out there is an open source project called the RepRap that is aimed at making a rapid prototype machine that can self replicate. I decided to fork the project and re-design all of the components to be machinable as the RepRap is made from plastic parts printed on a rapid prototype machine. The re-designed rapid prototype machine can be seen in the image below.

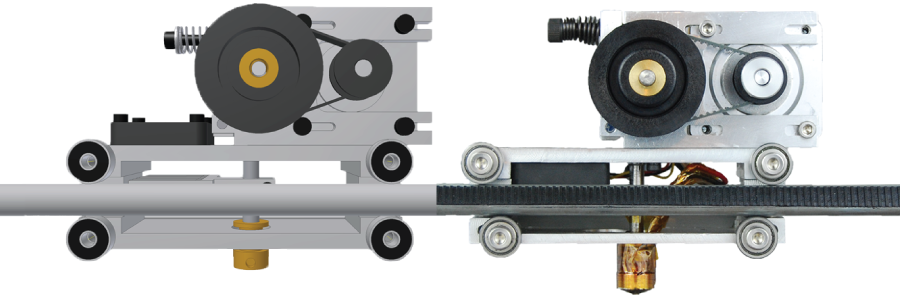

The original RepRap extrusion head performed extremely poorly, so I redesigned it for a Senior Design class. I analyzed all of the mechanical and thermal aspects of the head, and fixed all of the problems. The redesigned extrusion head can be seen in the image above, side-by-side with a CAD rendering of it.

A test part printed on the rapid prototype machine can be seen the left. The machine has a layer height of 0.014", which produces quite good parts. A second generation of the machine is in the works that is being designed completely from the ground up, building on what I have learned from this machine, and should be truly competitive with the best commercial 3D printers out there.